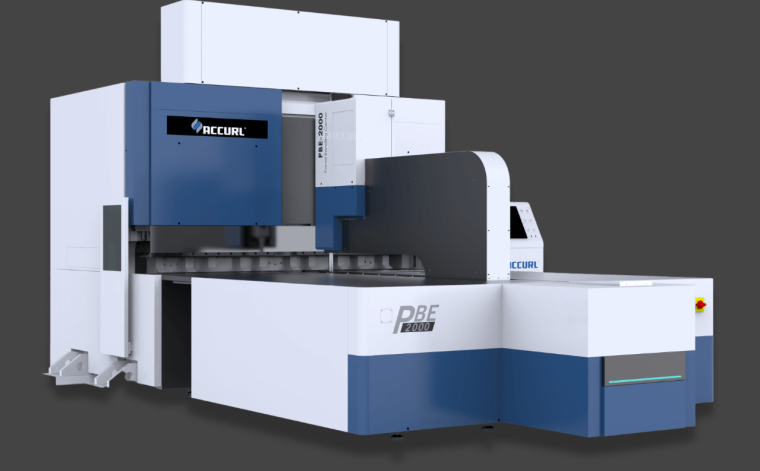

MACHINERY

ACCURL SMART Panel Bender

Introducing the ACCURL BEC SMART-Series Panel Bender, the ultimate solution for precision bending of sheet metal panels. Designed to meet the demanding needs of modern fabrication shops, this panel bender is built to provide unparalleled accuracy, efficiency, and flexibility.

The BEC SMART-Series features a user-friendly interface that makes it easy for operators to input the desired bending angles and dimensions. Its advanced control system ensures that each bend is executed with precise consistency, resulting in highly accurate and repeatable parts. This panel bender is capable of handling a wide range of materials and thicknesses, making it a versatile tool for any fabrication shop. Its sturdy construction and robust design allow it to handle even the most demanding applications, while its compact footprint makes it easy to integrate into any production line.

The BEC SMART-Series also boasts a range of advanced features that further enhance its capabilities. These include automatic crowning to compensate for material spring-back, advanced clamping systems for increased accuracy, and an innovative sheet support system that ensures flatness and stability during bending.

With its unparalleled precision, efficiency, and versatility, the ACCURL BEC SMART-Series Panel Bender is the perfect solution for any fabrication shop looking to improve their bending capabilities. Whether you're working on a small project or a large-scale production run, this panel bender is sure to deliver exceptional results every time.

- Fully automatic bending, high efficiency, energy saving and environmental protection.

- Bus control, which can be directly connected to the IOT(Internet of Things) for remote control and monitoring.

- Special high-load screw and guide rail structure, high load-bearing capacity, high positioning accuracy and long life.

- Fully automatic lubrication system, maintenance-free.

- C-arm feeding structure design, double servo rotation up and down, automatic downward press structure, rapid downward press, adjustable pressure, high rotation positioning accuracy.

- A/B axes: Positioning axes

- V axis: Feeding axis

- C/C11 axes: Rotation axes

- W/W11 axes: Pressing axes

- Z/Z11 axes: Tooling up & down motion axes

- Y/Y11axes : Tooling forward & backward motion axes

|

Name |

Unit |

BEC SMART-1400 |

BEC SMART-2000 |

BEC SMART-2500 |

|

|

Name |

Unit |

BEC SMART-1400 |

BEC SMART-2000 |

BEC SMART-2500 |

|

|

Max. Bending Length |

mm |

1400 |

2000 |

2500 |

|

|

Max. Sheet Width |

mm |

1500 |

1500 |

1500 |

|

|

Max. Bending Height |

mm |

170 |

170 |

170 |

|

|

Min. Workpiece Size (four sides bending) |

mm |

110×200 |

110×200 |

110×200 |

|

|

Min. Workpiece Size (single side bending) |

mm |

110 |

110 |

110 |

|

|

Min. Radius |

mm |

1.2 |

1.2 |

1.2 |

|

|

Bending Angle |

° |

±180 |

±180 |

±180 |

|

|

Max. Bending Speed |

s/bending |

0.5 |

0.5 |

0.5 |

|

|

Min. Sheet Thickness |

mm |

0.35 |

0.35 |

0.35 |

|

|

SS |

mm |

1.0 |

1.0 |

1.0 |

|

|

Max. Sheet Thickness |

MS |

mm |

1.5 |

1.5 |

1.5 |

|

AL |

mm |

2.0 |

2.0 |

2.0 |

|

|

Dimensions(L×W×H) |

mm |

3100x5300x2600 |

3100x6050x2600 |

3100x6050x2600 |

|

|

Full Power |

KW |

380V±10% |

380V±10% |

380V±10% |